Sales and Operations Planning, or S&OP, isn't just another bit of corporate jargon. Think of it as the central nervous system of your business, connecting what your sales team is promising to what your operations team can actually deliver. It’s the process that gets everyone—sales, marketing, operations, and finance—reading from the same script.

What Is Sales and Operations Planning Anyway?

We’ve all seen it happen. The sales team, fired up and closing deals, lands a massive new contract. It's a huge win! The problem? They're the only ones who know about it. Operations is completely blindsided, leading to a frantic scramble, production delays, and a less-than-impressed new customer.

This is exactly the kind of chaos S&OP is designed to prevent.

At its heart, S&OP is a formal, repeatable process that brings different departments together to create a single, unified game plan. It’s a structured way to constantly balance customer demand with your company’s ability to supply that demand, making sure you're not over-promising or under-delivering.

Why It’s More Than Just a Meeting

The real power of S&OP is that it shifts a business from being reactive to proactive. Instead of constantly putting out fires, you start anticipating changes in the market and preparing for them. A well-oiled S&OP process helps you nail down some critical goals:

- Sharpen Your Forecasts: By blending real-world sales intelligence with hard operational data, you get demand predictions you can actually trust.

- Get Everyone Talking: It demolishes the invisible walls between departments, creating a culture of shared goals and accountability.

- Smarter Resource Planning: You can fine-tune inventory, production schedules, and even staffing to meet demand without wasting time or money.

For many businesses across Canada, especially those dealing with tricky supply chains or unpredictable markets, S&OP has become a must-have. A typical plan looks ahead anywhere from 6 to 18 months, with most settling on a 12-month horizon to sync up with annual budgets. This forward-looking approach gives you the clarity to make big decisions with confidence.

The Five Steps of the S&OP Cycle

Sales and Operations Planning isn’t a one-off meeting you can just check off a list. It’s a continuous, repeating cycle. Think of it as a monthly rhythm that keeps your entire business in sync, turning a mountain of raw data into a single, unified strategy that everyone can act on. Each step logically builds on the last, making sure that by the time you're done, every department is working from the same playbook.

This cycle is typically broken down into five core stages, each with its own specific job and team of players.

Step 1: Data Gathering and Product Review

The whole process kicks off with a good old-fashioned information roundup. But this isn't just about grabbing last month's sales numbers. We're talking about a wide net that pulls in historical sales figures, current market trends, the impact of recent promotions, and what your production team can realistically handle.

At the same time, your product management team is taking a hard look at the product lineup. They’re analyzing where each product is in its lifecycle, planning for new launches, and flagging any items that are on their way out. This first step is all about building the entire plan on a solid foundation of accurate, relevant information.

Step 2: Demand Planning

Once the data is in, the spotlight shifts to forecasting what your customers will actually want to buy. This is where your sales and marketing teams really shine. They dig into the data, add their on-the-ground market knowledge, and factor in any upcoming promotions or marketing campaigns.

The main goal here is to create an unconstrained forecast. This is essentially a best-guess prediction of what customers would buy if you had absolutely no supply issues. This forecast is the first major piece of the S&OP puzzle.

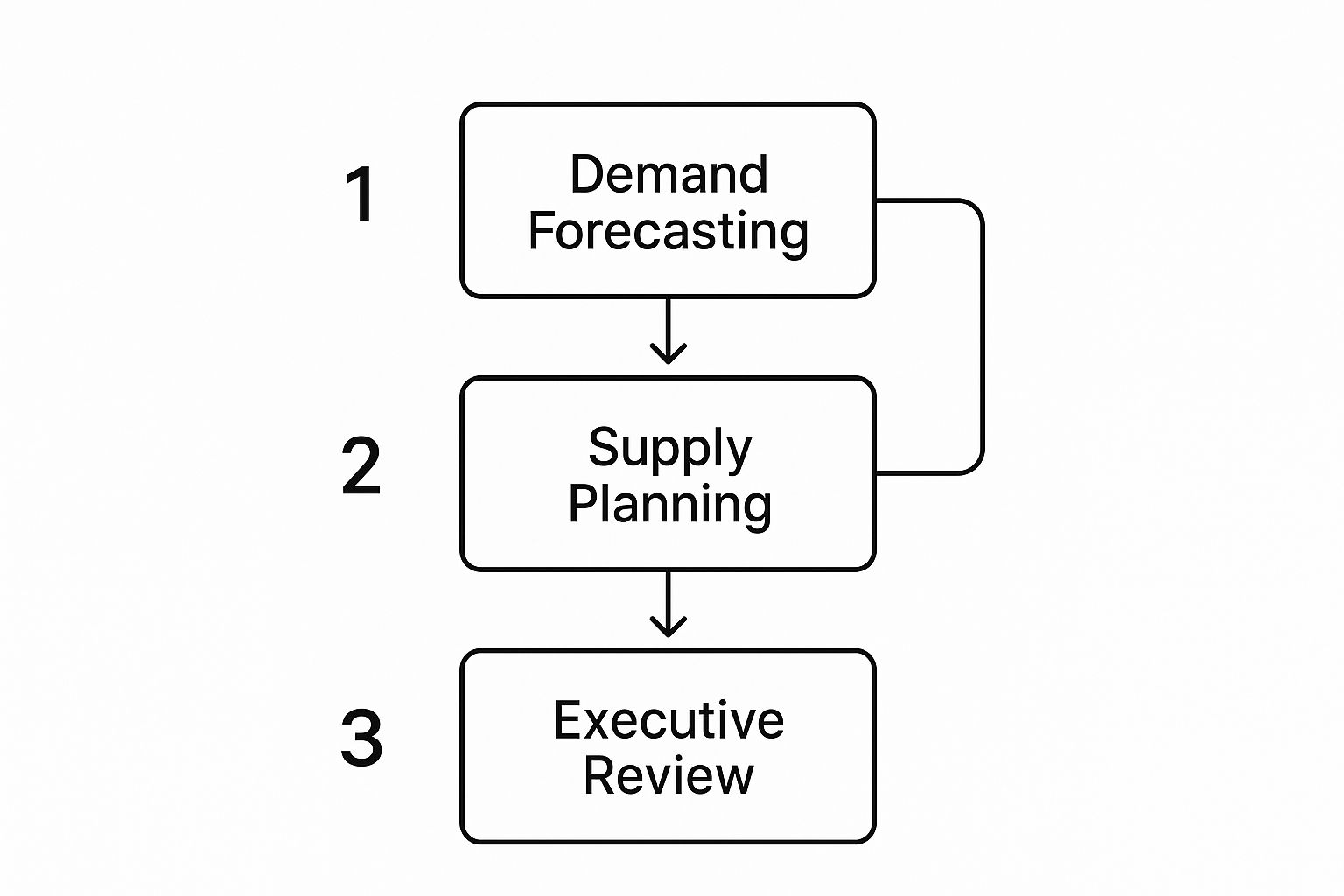

The flow chart below shows how this demand forecast becomes the starting point for the supply plan and, eventually, the final executive review.

As you can see, the insights from the demand side directly feed into what the supply side needs to prepare for, all leading up to a final strategic decision.

Step 3: Supply Planning

Now, it's time for the operations, supply chain, and procurement teams to get involved. Their job is to take that optimistic demand plan and see if it’s actually possible. Can the factory make that much product? Do we have enough raw materials on hand? Is there enough space in the warehouse and enough trucks to ship it all?

This stage is all about creating a constrained supply plan. It’s a reality check that pinpoints the real-world gaps, bottlenecks, or constraints that might stop you from meeting every single order. It grounds the forecast in what your business can actually do.

Step 4: The Pre-S&OP Meeting

Before getting the top brass involved, key managers from every department gather for a pre-S&OP meeting. Think of this as a working session to hammer out the details and get aligned. The group lays the demand and supply plans side-by-side, calls out any major differences, and starts brainstorming solutions.

They’ll run through different "what-if" scenarios, like:

- Can we run overtime in the factory to boost capacity?

- Should we adjust a marketing promotion to shift demand to a different product?

- Do we need to build up inventory now to prepare for a big sales spike next quarter?

The goal is to solve as many problems as possible and cook up a clear summary with solid recommendations for the final decision-makers.

Step 5: The Executive S&OP Meeting

This is the grand finale. The cycle wraps up with the executive S&OP meeting, where senior leaders from sales, marketing, operations, and finance all sit down at the same table. They review the consolidated plan, the remaining gaps, and the solutions proposed during the pre-S&OP session.

This isn't a meeting for getting lost in spreadsheets; it's a high-level, strategic conversation. Here, the executive team makes the final, binding decisions on how the company will balance supply and demand. Their approved strategy becomes the one and only operating plan for the entire organization, giving everyone clear marching orders for the month ahead. Then, the cycle begins all over again.

Real-World Benefits of S&OP

Putting a Sales and Operations Planning (S&OP) process in place is about so much more than just adding another meeting to everyone's calendar. It’s a genuine strategic shift that pays off in real, measurable ways that hit your bottom line. When your sales forecasts actually talk to your operational capabilities, the entire business runs smoother, smarter, and more profitably.

One of the first things you'll notice is a massive improvement in how you manage inventory. It's a classic problem: too much of the stuff that isn't selling, and not nearly enough of what customers actually want. This kind of mismatch leads to expensive overstock, wasted space in the warehouse, and frustrating stockouts that can really damage customer trust.

S&OP cuts through that noise. It gives everyone across departments a clear line of sight, helping you keep inventory at that sweet spot—enough to meet demand without having cash needlessly tied up in products just sitting on a shelf. This is a direct line to better cash flow and lower carrying costs.

Taming Supply Chain Chaos

Beyond just what's in the warehouse, S&OP brings a sense of calm to your entire supply chain. It's the perfect antidote to the "bullwhip effect," that chaotic ripple where a tiny, unexpected shift in customer demand creates huge, disruptive waves all the way back to your suppliers. The result? Total havoc for production schedules, vendors, and logistics.

Think of S&OP as a shock absorber. By getting everyone to agree on a single, unified demand plan, it smooths out those volatile signals. For manufacturers in Canada looking to grow, this is absolutely critical. A solid S&OP process can dial down supply chain volatility, unlocking major cost savings. In fact, research shows Canadian firms can slash excess inventory by 15-20% while boosting service levels by 10-15%.

Enhancing Team Efficiency and Focus

Finally, a well-oiled S&OP process makes your teams dramatically more efficient. When sales, finance, and operations are all working from the same playbook, that constant internal friction just melts away. All the time that was once wasted arguing over whose spreadsheet was right can now be spent hitting shared business goals.

This united front also leads to sharper decision-making. When everyone is looking at the same information and understands the trade-offs, leadership can make faster, more confident calls on where to put resources.

For your field sales reps, this means they get clearer targets and can count on product being available when they make a sale. Better alignment ensures every lead has a much higher chance of converting, a key idea behind the best practices for lead routing that boost sales efficiency. It's about getting the whole organisation moving in the same direction, with purpose.

Navigating the Inevitable S&OP Roadblocks

Rolling out a Sales and Operations Planning (S&OP) process is a fantastic goal, but let's be realistic—it's never a simple flick of a switch. The path is almost always littered with a few roadblocks, and if you’re not ready for them, they can stall your progress before you even get started.

Knowing what to expect is half the battle. So, let’s talk about the most common hurdles you'll likely face and how to get over them.

Breaking Down Old Habits

One of the biggest obstacles isn't a system or a process; it's people. Specifically, it's the departmental silos that have likely been built up over years. Sales has its targets, operations has its production schedules, and finance is watching the budget. They’ve all been running in their own lanes.

Suddenly, you're asking them to merge into one big, collaborative highway. It’s no surprise that this can cause some friction. Teams naturally protect their own turf and metrics, making it tough to rally everyone around a single, unified plan.

This leads directly to another human element: a natural resistance to change. People get comfortable with their routines. Introducing something as comprehensive as S&OP can feel like a major disruption, causing team members to drag their feet or disengage entirely.

The Trouble with Data and Leadership

Then there's the data problem. Good S&OP is fuelled by good information—it has to be accurate, timely, and trusted by everyone involved. But in reality, most businesses are wrestling with data that's messy, siloed in different software, or just plain out of date. If your teams don't trust the numbers, the whole planning process grinds to a halt.

And perhaps the most critical piece of the puzzle is leadership. If your executive team isn't visibly and vocally championing the S&OP process, everyone else will see it as just another "flavour of the month" initiative. Without that top-down support, you'll struggle to get the resources you need and to underscore just how important this new way of working is.

A huge part of this is learning how to balance what you can sell with what you can actually produce. This becomes even trickier when you’re already managing resource constraints effectively.

Getting ahead of these common issues can make all the difference between a frustrating S&OP rollout and a successful one. The table below breaks down some of the most frequent challenges and offers some practical ways to tackle them head-on.

S&OP Implementation Challenges and Solutions

table block not supported

By treating these challenges not as surprises but as predictable parts of the journey, you can build a solid action plan. This proactive approach will help you navigate the bumps in the road and unlock the real power of a well-run S&OP process.

Choosing the Right S&OP Tools

Picking the right software for your sales and operations planning is a bit like choosing the right pair of work boots for your field team. The perfect fit provides support and prevents problems down the road, while the wrong one can cause a world of pain.

When Excel Works and When It Falls Short

For many small and growing field sales teams, Excel is the default starting point. It's familiar, it's accessible, and it lets you start tracking forecasts without a big software investment. You can get a basic system up and running pretty quickly.

But let's be honest, that's where the fairy tale often ends. As your business grows, those manual updates become a huge time sink, and the risk of a simple typo throwing off your entire forecast skyrockets.

- The Good Side of Excel:

- The Not-So-Good Side:

For a small team with a straightforward S&OP cycle, Excel can work in a pinch. But the moment your data gets more complex or your team expands, its limitations become glaringly obvious.

Exploring Mid-Tier Planning Platforms

Once the pain of managing multiple spreadsheets becomes too much to ignore, it’s time to look at dedicated, mid-tier cloud tools. This is where you really start to see the benefits of a proper S&OP system.

These platforms are designed to automate the grunt work and give everyone a single source of truth. Think shared dashboards, automated alerts when a forecast is updated, and basic modelling to help you see what’s coming.

In fact, Canada’s manufacturing sector has seen a 10.5% compound annual growth rate in S&OP software adoption between 2021 and 2026. Businesses that make the switch are reporting 20-25% reductions in excess inventory and 15% fewer stockouts.

If you want to take your analysis even further, exploring tools for AI-Powered Business Intelligence can layer predictive insights onto your S&OP process, helping you anticipate trends instead of just reacting to them.

Properly aligning your sales forecasts with your leads is also critical. To help with that, you might find our article on the 10 best lead management software for sales teams in 2025 useful.

Choosing Scalable S&OP Software

Eventually, your team might even outgrow the mid-tier options. When that happens, you’ll be looking at more robust, modular enterprise suites that can be customized to your exact needs.

These systems offer powerful features like drag-and-drop scenario planning, fully integrated inventory optimization, and highly advanced reporting that connects every piece of your operation.

When you're evaluating these bigger platforms, here’s what you need to focus on:

- Integration: How well does it connect with your existing CRM and ERP systems? This is non-negotiable.

- Usability: Is the interface intuitive enough for your field reps to actually use it without extensive training?

- Cost: What’s the pricing model? A recurring subscription is very different from a one-time perpetual license.

- Support: What kind of vendor support and community resources are available when you run into trouble?

A smart approach is to roll out the new software in phases. Let your team get comfortable with the core features first before you try to implement the entire suite.

Ultimately, the goal is to find a tool that matches your team’s current size, budget, and technical skills. This ensures your S&OP process can stay nimble and effective, helping you adapt and grow without being held back by your software.

Common Questions About S&OP

Even with a great plan, it's natural to have questions when you're introducing something as big as Sales and Operations Planning. Getting clear, straightforward answers is crucial for getting everyone—from the executive team right down to your field reps—on the same page and confident in their roles.

Let's tackle some of the most common questions that pop up when leaders and managers first start exploring S&OP.